The crispy chicken fillet production line is a set of specially designed production plants for making crispy chicken fillets or chicken nuggets. The raw materials for making chicken fillet is the whole chicken breast. This fried chicken breast plant is mainly composed of the vacuum tumbler, chicken fillet cutting machine, paste battering machine, bread crumbs coating machine, and frying machine.

Table of contents

chicken fillet vs chicken breast

Chicken fillet and chicken breast are actually inclusive. This is because chicken fillets are usually strips of chicken cut from a whole piece of the chicken breast through a stripper. Large chunks of chicken breast cannot usually be made directly into food but must be further processed into fried chicken nuggets, fried chicken fillets, and popcorn chicken.

How to make fried chicken fillets with the chicken fillet production line?

The production process using the crispy chicken production line mainly includes marinating chicken breast, cutting chicken breast into strips, breading with batter, breadcrumbs coating, and frying.

Step 1 To marinate the chicken breast

We can use the vacuum tumbler to stir and marinate the chicken breast pieces. The vacuum state of the tumbler will expand the chicken, salt and other seasonings will soak into the meat, which makes the meat of the chicken breast tender and even taste.

Technical parameter:

Power: 2.25kw

Output: 100kg/can

Size: 1410*1000*1450mm

Step 2 To collect the marinated chicken breasts

After the pickling is completed, the vacuum tumbler will reverse, so the pickled materials will be discharged from the barrel. We can use a manual cart to hold the marinated chicken breasts. The bottom of this stainless steel feeder has wheels for easy movement.

Technical parameter:

Volume: 200L

Size: 780*660*660mm

Step 3 Manually thread the marinated chicken breast

The processing of fried chicken fillet can take the form of skewers and without skewers. Because the fried chicken fillet that is processed in large quantities is generally sold because we can manually thread the chicken breast.

Place the marinated chicken on this stainless steel board, and then manually skewer large pieces of chicken breast with stainless steel or bamboo skewers.

Technical parameter:

Size: 1000*800*1000mm

Step 4 Chicken fillets forming

The chicken fillet forming machine can replace a lot of manual labor and automatically cut the chicken breast into a fixed shape. Moreover, users can change different molds to make fried chicken fillets of different shapes.

Technical parameter:

Power: 0.6kw

Size: 1460*620*1290mm

Step 5 Paste battering

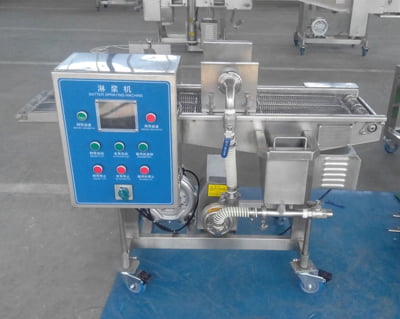

Then, we can use the automatic battering machine to evenly coat the surface of the cut chicken fillets with a layer of grout.

Technical parameter:

Power: 0.45kw

Output: 50-100kg

Size: 1390*550*1320mm

Step 6 Bread crumbs coating

Next, we can wrap the chicken fillet soaked in batter with flour or bread crumbs using an automatic coating machine. The chicken fillet that is breaded and fried will be brighter in color.

Technical parameter:

Power: 1.2kw

Output: 200kg

Size: 1680*550*1480mm

Step 7 Chicken fillet frying

The last step in making fried chicken fillets using the crispy chicken fillet production line is to use an automatic food fryer to deep frying the breadcrumbs. The frying temperature is 160℃-180℃, and users can set different frying temperatures according to the different materials they make.

Technical parameter:

Power: 36kw

Output: 100kg/h

Size: 1400*1200*1600mm

Main features of this crisp chicken fillet production line

1. The processing technology of the fried chicken fillet production line is relatively simple, the workers are easy to operate, and the production efficiency is high.

2. The output of this chicken fillet processing plant is 100kg/h, which can actually be even larger. The chicken fillet production line is customized by us for foreign customers. In addition, we can also customize the fried chicken fillet production line with larger output according to the specific needs of customers, such as 150kg/h, 200kg/h, 300kg/h or more.

3. All equipment of this fried chicken breast plant is made of high-quality 304 stainless steel, so it is very resistant to wear and corrosion, has a low failure rate and a long service life, which can create greater benefits for users.