The fried crunchy coated peanuts production line also called the spicy coated fried peanut processing plant or Masala coated peanuts making machines, which can replace much labor work to make crispy coated peanuts on a large scale. This fried coated peanut line mainly include the jacketed cooking kettle, peanut coating machine, frying machine, cooling machine, seasoning machine and packaging machine.

Table of contents

Main features of the crunchy fried coated peanuts

Crispy coated peanuts are a popular snacks in many countries. The main ingredient is peanut kernels, the ingredients are wheat flour, starch, and the seasoning is peanut oil, salt, and seasoning powder. It is made by coating and frying.

The main feature of this crunchy coated peanuts is golden color and crispy taste. Due to different specific processing methods, this deep-fried coated peanut tastes different in many countries and is called differently. The common ones are spicy crunchy peanuts, peanut burger snack, Masala coated peanuts, Besan coated peanuts, etc.

Why choose the crunchy coated peanut production line?

As a common fried snack, spicy coated peanuts are in high demand in many countries. The traditional small workshop production method has low production efficiency, an unhygienic production process, and a single taste of processed products.

Using small and medium-sized fried coated peanut production line to produce spicy coated peanuts has great advantages. The processing line has the characteristics of large output, various types of finished products, labor and cost saving, and can meet the production needs of small and medium-sized food processing plants.

The composition of the crunchy coated peanuts production line

Machine list of the Masala coated peanuts processing line

| NO. | Equipment name |

| 1 | Jacketed cooking pot |

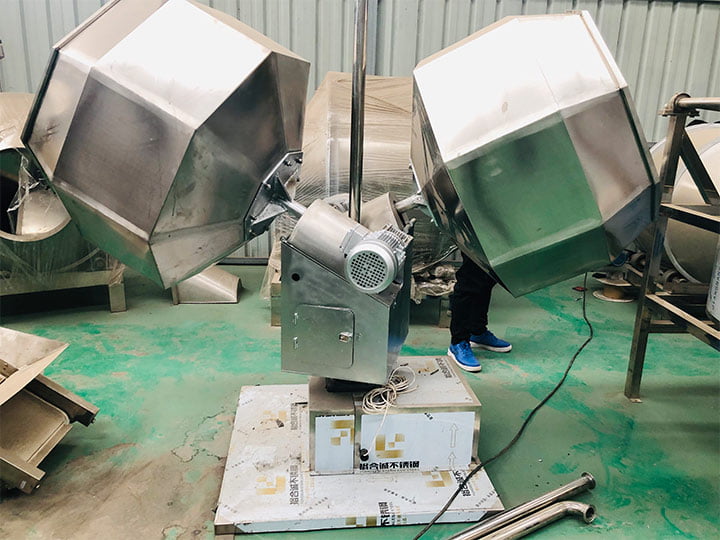

| 2 | Peanut coating machine |

| 3 | Frying machine |

| 4 | Seasoning machine |

| 5 | Air cooling machine |

| 6 | Packaging machine |

Processing steps of the crunchy coated peanuts

Step 1 Peanut kernels selection

The peanut kernels can be classified by a screening machine. Coated peanuts should generally use small peanut kernels. If you use large peanut kernels, you can fry half-cooked peanuts before coating. The peanut kernels used should be uniform in particle size and clean.

Step 2 Cooking syrup liquid

Use a jacketed cooking pot to boil white granulated sugar, sucrose, or other types of sugar at a temperature of 70°C for a few minutes to melt into a thick liquid. Then cool down for use.

Step 3 Peanut coating

Coating peanuts can be divided into two forms. The first is to coat peanuts only with a paste prepared from glutinous rice flour. The second is to use syrup, refined flour and starch to coat peanuts. Pour the peanut kernels into the coating machine, pour the syrup (paste) first, and then sprinkle the coating powder after the slurry is evenly attached, and coat the peanuts evenly with a layer of coating powder.

Step 4 Frying with a deep fryer

Put the coated peanuts into the deep fryer for frying. The oil temperature is about 160°C-170°C, and the frying time is about 8 minutes. After the coated peanuts are fried, they will be golden. The commercial fryer has the function of automatic feeding and discharging, which can ensure safe production.

Step 5 Coated peanuts seasoning

After the coated peanuts are fried, the automatic seasoning machine can be used for seasoning. Users can add the prepared seasoning powder to the seasoning machine according to their own crunchy coated peanut recipe. During the continuous rotation of the seasoning machine, the coated peanuts will be evenly covered with a layer of seasoning.

Step 6 Cooling

In fact, the coated peanuts will gradually cool down during the seasoning process, but they will still have a high temperature. Therefore, we need to use this air cooling machine to lower the temperature of spicy coated peanuts to room temperature.

Step 7 Fried coated peanuts packaging

After the masala coated peanuts are cooled, we can use this vertical granule packaging machine to divide the coated peanuts into bags. We can also use vacuum packaging machines to pack and pack them with nitrogen.