The popcorn chicken production line( or chicken popcorn processing line) is a complete set of equipment composed of a series of popcorn chicken machines, which can process fresh chicken breast into instant chicken popcorn and frozen chicken popcorn in a short time. The commercial chicken popcorn making machines can be customized with different outputs and models according to customer needs.

What is popcorn chicken?

The popcorn chicken was originally a kind of delicious fried food launched by KFC. Because of its golden appearance and crisp taste, it was loved by many young people. With the gradual popularity of such snacks, people of all ages now love to eat chicken popcorn, so its market potential is great.

In addition to KFC selling popcorn chicken, many food processing plants have begun to sell large quantities of processed chicken popcorn and frozen chicken popcorn to supermarkets and various restaurants.

Ready-to-eat popcorn chicken VS frozen popcorn chicken

Under normal circumstances, the chicken popcorn we buy in KFC or other fast-food restaurants is freshly fried chicken popcorn products that can be eaten directly.

The bagged chicken popcorn purchased in supermarkets is usually frozen chicken popcorn made by fried food processing plants. The frozen chicken popcorn was only slightly fried when processed in the factory, so we need to re-fry the chicken popcorn before eating it.

How to make popcorn chicken with the popcorn chicken production line?

The chicken popcorn production line used by the fried food processing factory mainly includes the following equipment: 1. Chicken cutting machine; 2. Conveyor; 3. Dipping machine; 4. Powder coating machine; 5. Vibrating conveyor; 6. Frying machine; 7. Cooler. The specific processing flow of the chicken popcorn production line is as follows:

1.Chicken meat cutting

The chicken breast cutting machine is specially used to cut fresh boneless meat into uniform size blocks. If it is chicken with bones, we can also provide the corresponding cutting machine.

2. Conveyor transporting

The main function of this conveyor is to transport the cut chicken pieces to the next working link, and realize the automation of the chicken popcorn production line.

3. Meat cubes screening machine

The linear sieving machine has multiple sieving functions and is made of 304 stainless steel. It is often used in food processing. Through continuous vibration, the machine can screen the cut chicken breast pieces with different sizes, so as to select the meat pieces with uniform size.

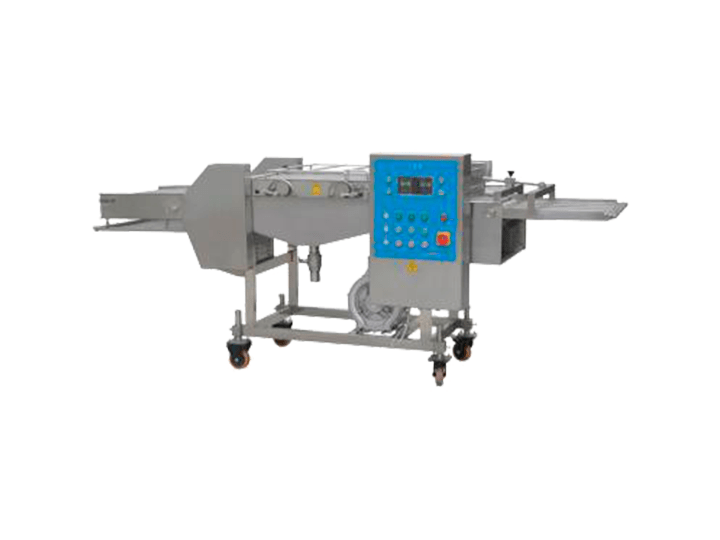

4. Batter dipping

This automatic dipping machine is entirely made of stainless steel and is mainly composed of conveyor belt and spraying system. Its main purpose is to uniformly cover the surface of the food with a layer of pulp to facilitate the subsequent processing.

5. Flour coating

After dipping, the material will be automatically transferred to the powder coating machine for even powder coating (mainly flour). The powder box of this machine has the functions of automatic weighing and automatic unloading, so every piece of meat can be evenly powdered.

6. conveyor transporting

The conveyor is widely used in automatic production lines. The role of this link is mainly to transport the powdered chicken nuggets to a mesh belt fryer for frying.

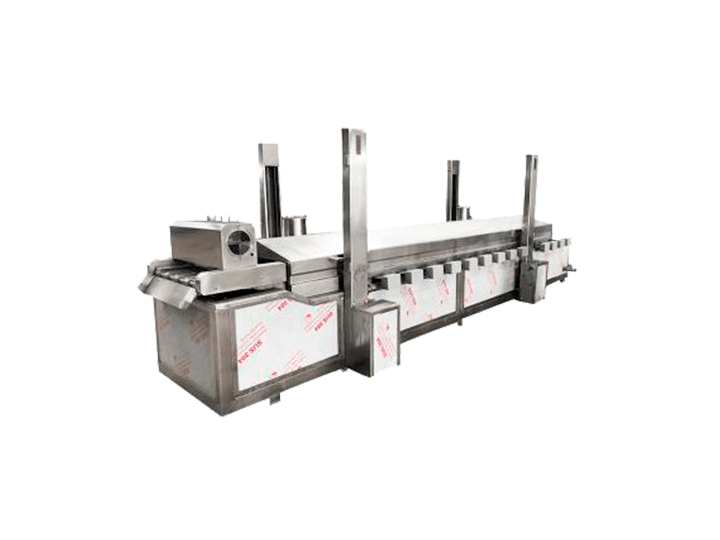

7. Continuous frying

The continuous fryer is also called a mesh belt fryer and is currently the best equipment for processing fried food in large quantities. The heating method of the fryer is gas and electricity. When frying chicken popcorn, the oil temperature is about 160°C. We can customize frying equipment with different sizes and different outputs according to different customer needs.

8. Popcorn chicken air-cooling

The chicken popcorn must be cooled in time after being fried before it can be packaged. The air dryer is mainly composed of a conveyor belt and a group of high-speed fans. When the fried chicken popcorn passes through multiple sets of fans, it will be quickly cooled to room temperature, which is convenient for the packaging process.

Main features of the popcorn chicken making machines

1. In addition to using this chicken popcorn production line to produce boneless chicken popcorn, we can also use these chicken popcorn processing machines to produce boned chicken popcorn and frozen chicken popcorn.

2. All the equipment of the whole popcorn chicken production line is made of high-quality 304 stainless steel, so it is very durable and has a longer service life.

3. Our chicken popcorn production line is not only suitable for the processing of ready-to-eat chicken popcorn in fast food restaurants and restaurants, but also very suitable for large-scale and small-scale food processing plants to process large amounts of frozen chicken popcorn.

4. This commercial rice popcorn making machine has a high investment cost performance because of its favorable price and high production efficiency. As a delicious food, chicken popcorn has growing market demand. Therefore, this set of equipment has great market potential.