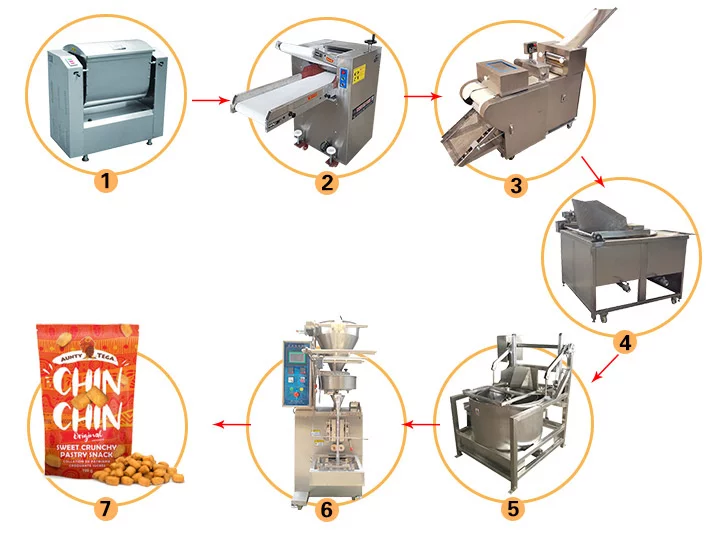

Taizy fried chin chin production line is designed for making crisp chinchin snacks for many West African countries, like Nigeria and Ghana. The chin chin processing line mainly includes the dough mixer, dough sheet press machine, chin chin cutter machine, frying machine, deoiling machine, and fried chin chin packaging machine.

Commercial production of fried chin chin can be realized with the help of commercial chin chin making machines. At present, many investors engaged in traditional food production have begun to pay attention to chin chin business.

Working video of the chin chin production line

Why do many African customers choose Taizy chin chin making machines?

- Good product quality. Our chin chin making machines are all made of food grade stainless steel, which is resistant to wear and corrosion. Therefore, customers are highly satisfied and are more willing to introduce their friends to buy our chin chin machine.

- The high degree of automation. Our automated chinchin production line can produce 50-300kg of chin chin per hour, compared to the traditional way of making chinchin by hand.

- Good after-sales service. No matter which country our chin chin production line is exported to, we will do our best to provide good after-sales services. For example, we can provide detailed machine installation videos, equipment instructions, and maintenance skills to our customers.

- Good production returns. Many African customers purchase our chin chin processing line to mass-produce and sell chin chin snacks. They even exported fried chin chin to other countries, thus making huge profits. Chin chin processing business not only increases the income of investors but also promotes the employment of local labor.

Fried Chin Chin Snack Production Process

The whole production process of the chin chin production line: soft dough mixing–dough sheets pressing–chin chin cutting–chin chin frying–deoiling and seasoning–chin chin packaging.

Machine list of the chin chin production line

| No. | Machine name |

| 1 | Dough mixer machine |

| 2 | Dough sheet press machine |

| 3 | Chin chin cutter machine |

| 4 | Chin chin frying machine |

| 5 | Electric deoiling machine |

| 6 | Chin chin snacks packaging machine |

Detailed description of the machine for making chin chin

As mentioned above, there are at least 6 machines that are needed to make chinchin. I will introduce these chin chin making machines to you in detail below.

Dough mixing—dough mixer machine

This electric dough mixer is commonly used as kneading equipment, which can quickly mix all kinds of flour.

In different types of dough mixing machines, the processing capacity of each batch is different, such as 15kg, 25kg, and 50kg.

The dough kneading machine has an automatic mixing device and can tilt the discharge. It’s simple to use. When dough mixing, users can also add appropriate seasonings to the dough.

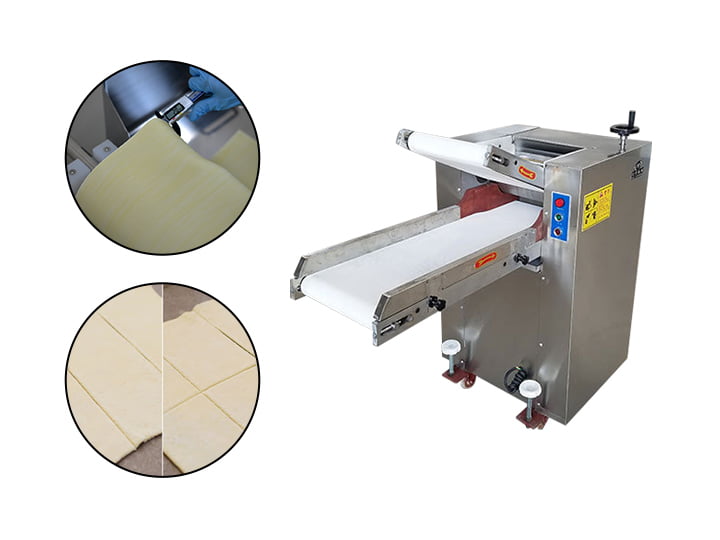

Dough sheets making—dough sheet press machine

The automatic dough sheet press machine is made of high-quality stainless steel, which is strong and durable. It can roll the dough repeatedly to form dough sheets of uniform thickness.

After being processed by the dough sheet maker, the density of the dough will increase. And it will be tougher, which can make the chin chin taste better.

In addition, users can adjust the thickness of the dough sheets according to different needs.

Chin chin cube cutting—electric chin chin cutter machine

After the dough sheets are processed, we need to use a chin chin cutting machine to quickly cut these dough sheets into even-sized strips or cubes.

The cutting blades of the chin chin cutter can be removed and replaced. Therefore, users can process chin chin of various shapes by changing different cutting blades.

This chin chin cutter machine is an important equipment in the chin chin production line.

Chin chin frying—deep fryer machine

When frying chin chin cubes in large quantities, this round deep fryer machine will be a good choice.

The chin chin frying machine has the function of automatic feeding and discharging, which can avoid scalding during manual feeding.

Moreover, the fryer machine is very practical and can be used to fry various foods. The temperature of the frying chinchin is about 160°C, and the frying temperature can be adjusted.

Deoiling—deoiling machine

Fried chin chin snacks will contain a lot of oil droplets just after being fried. So, we need to use this electric deoiler to quickly degrease them.

The deoiling machine can remove excess oil droplets on the surface of the chin chin, making the fried chin chin taste better.

In addition, processors can use a seasoning machine to season fried chin chin according to their needs.

Fried chin chin packaging—chin chin packaging machine

This vertical chin chin packaging machine is often used for packaging granular items, especially suitable for packaging various snacks.

When using this snack packaging machine, we can customize the weight and packaging style.

In addition, chin chin packaging can be filled with nitrogen. This is the last step of the chin chin production plant.

What is the traditional Nigerian chin chin recipe?

Chin chin is a common fried snack in many West African countries, so there are various chin chin processing recipes. The traditional Nigerian fried chin chin recipes are very simple.

First, you need to mix flour, baking powder, and nutmeg powder, and then add butter and knead it to form a breadcrumb shape. Next, you should mix the eggs, milk, and sugar and pour them into the flour to form a smooth, soft dough.

Then you need to roll out the dough into a thin sheet and cut it into small squares or long strips. Then you should fry the cut strips in hot oil until golden brown. Finally, you need to drain the excess oil and add your favorite seasoning, and serve.

Why make Nigerian chin chin snacks with a chin chin production line?

With the tremendous progress of science and technology, our social productivity has gradually improved. And the social demand for fried food is increasing. At present, food processing is no longer dependent on manual production but is produced through advanced food processing equipment.

The fried chin chin in Nigeria is the same. With the increasing demand, many processors choose to use commercial chin chin production lines for mass production. Automatic chin chin making machines can not only meet the needs of the local market but also export this delicious Nigerian chin chin snack to other countries.

How to start a chin chin business in Nigeria?

- First, you need to identify your target market and understand user preferences. Chin chin is popular among all age groups, but specific flavors or packaging may appeal more to certain groups.

- In addition, you need to register your company and apply for permits and licenses.

- Next, you will need to choose a location suitable for production and purchase chin chin making machine. If you are going to produce chinchin snacks in large quantities, then sourcing a chin chin production line is necessary.

- You will then need to source high-quality flour, sugar, milk, eggs, butter, and other ingredients.

- Next, you need to create a memorable brand name and packaging design.

- Finally, you need to sell your products through local markets, supermarkets, schools, offices, and online platforms with delivery services.

What is the production capacity of this line?

Depending on the configuration, the production capacity of the QinQin line ranges from 100kg/h to 2000kg/h.

Can production lines be customized based on my facility layout or recipe requirements?

Yes. We can provide customized design solutions tailored to your factory dimensions, target output, and product type.

What about the after-sales service for the equipment?

We provide comprehensive after-sales service, including installation and commissioning guidance, video training, spare parts supply, and long-term technical support.

Contact us for the latest quotation!

So far, our chin chin machine has been exported to Ghana, Nigeria, Cameroon, Togo, and many other countries. Do you want to know the latest price of our chin chin production line? Welcome to contact us through the contact information in the lower right corner. We will reply to you as soon as possible.