The electric chin chin cutter machine is an important piece of equipment for processing traditional Nigerian snacks, which can quickly cut dough into small pieces of various shapes and sizes. At the same time, this commercial chin chin cutting machine is also the common pretreatment equipment for the fried chin-chin snack processing line.

Working video of commercial chin-chin cutting machine

Why use an electric chin chin cutter?

Today, in many parts of Africa, food and snack processing are no longer just homemade methods, but large-scale production through food processing plants. Especially when processing fried chin chin snacks, many food factories and restaurants choose to buy electric chin chin cutting machines instead of manually cutting dough.

This fast cutter machine can quickly press the dough into sheets and then cut them into even-sized cubes or strips. This machine has high processing efficiency, can replace tedious manual labor, and has a good cutting effect, which is very suitable for chin chin making plants.

How does the automatic chin chin cutting machine work?

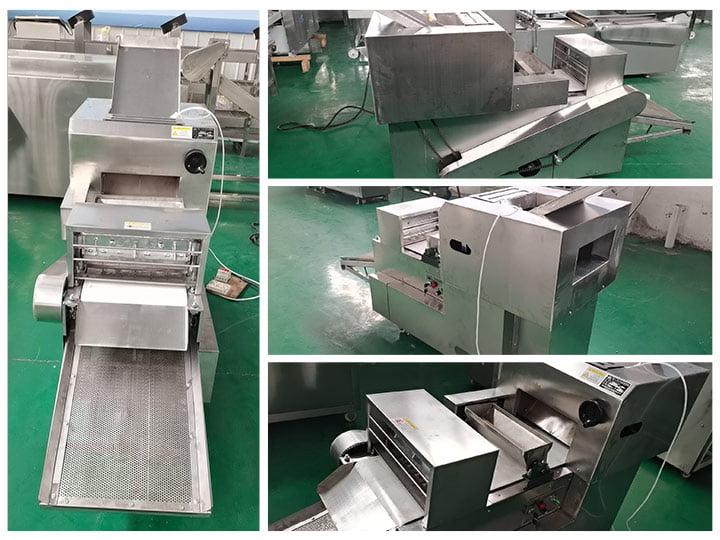

This multifunctional pasta cutting machine has a compact structure and mainly has two functions: dough sheet pressing and cutting.

The first part of the machine is mainly a dough sheets pressing structure, which can fully squeeze large pieces of dough to form dough sheets with uniform thickness. And we can adjust the thickness of the dough sheets by adjusting the gap between the pressing rollers.

The other part of the machine is mainly a fast cutting device. We can process pasta pieces of different shapes and sizes by changing different cutters and adjusting the distance between the blades.

The chin chin cutter machine is often equipped with a small electric control cabinet that can control the entire processing process. Moreover, there is an automatic powder box in the middle of the machine, which can evenly sprinkle a layer of flour on the pressed dough sheets, otherwise, the dough sheets stick together.

How to use a chin chin cutter?

Mastering how to use a chin chin cutter ensures seamless dough processing.

Adjustment of the pressing roller

Begin by adjusting the pressing rollers to achieve the desired dough sheet thickness, allowing flexibility for diverse recipes.

Distance between switching blade and tool

Then, customize the pasta shapes by switching cutters and adjusting blade distances.

Turn the switch on

When the worker turns on the switch the machine can automatically cut the chin chin dough.

This electric-powered multifunctional cutter simplifies the entire process, enhancing efficiency in creating various chin chin sizes and shapes. Additionally, the built-in control panel streamlines operations, while the automatic powder box prevents dough sticking, guaranteeing smooth, uniform results. Explore our comprehensive guide on utilizing the electric chin chin cutter for effortless and versatile snack production.

Technical parameters of the electric chin chin cutter machine

| Name | Chin Chin Cutter Machine |

| Power | 1.5 kw |

| Capacity | 50-100 kg/h |

| Thickness Range | 0-30 mm |

| Cutting Range | 23.5~188(length) 2~40(width) |

These are the technical data of our electric chin chin cutter. From the table, we can see that the output of this machine is 50-100 kg/h. The thickness of chin chin that can be cut by the machine ranges from 0-30 mm. Do you need this electric chin chin cutter? If interested please feel free to contact us, and we will reply to you as soon as possible.

Applications of the Nigerian chin chin making machine

This Nigerial chin chin making machine can cut the kneaded dough into cubes, strips, moon shapes, round shapes, triangles, hexagons, etc. And we can also customize the cutting units based on the customers’ needs. After being formed by this chin chin cutter, the user can use a deep fryer machine to fry the dough pieces for making crisp snacks. This machine is always used in the chin chin production line.