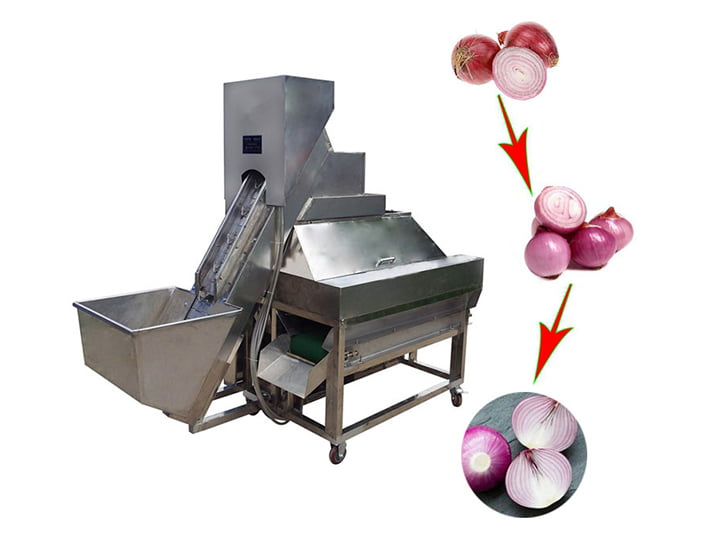

The electric onion ring cutter machine is manufactured for cutting clean onions into onion rings or onion slices. The onion rings’ thickness can be adjusted between 2mm-5mm with the machine. Of course, before cutting the onions, we should do onion peeling and root cutting with the onion peeling machine. This machine is also essential for making crispy onion rings.

Why use an onion ring cutter?

Anyone who has cut an onion should know that its spicy smell always makes us cry. Therefore, it is not feasible to cut onions manually when processing onions in food factories.

Commercial onion ring cutting machines can not only imitate the effect of manual cutting but also make the thickness of the onion ring uniform.

Most importantly, the processing efficiency of the onion ring cutting machine is very high, basically three times that of manual cutting. In addition, the use of onion cutters is safer, and can effectively avoid manual cutting injuries.

The main structure of the onion ring cutter machine

The structure of the onion ring cutting machine is very compact, mainly composed of a frame body, a motor, a feed port, a discharging port, and a cutting blade. To ensure food safety and long service life, the machine is mainly made of high-quality 304 stainless steel.

The feed port of the onion ring cutter machine is usually four circular cylinders with different diameters. The feed inlet is designed in this way to adapt to different raw materials, such as cucumber, potato, etc. For onions of different sizes, we can use different inlets.

What is the price of a commercial onion ring slicer machine?

When delving into the market for a commercial onion ring slicer machine, the price spectrum varies widely based on several crucial factors. These include the slicer’s capacity, material quality, cutting mechanism, and brand reputation.

Onion ring cutter machines, equipped for high-volume usage in restaurants or food processing units, can range significantly in price. Entry-level models might start around $1000 to $2000, offering basic functionalities and moderate slicing capacities.

Meanwhile, more advanced, heavy-duty machines with enhanced features, stainless steel construction, precise cutting options, and higher output rates may range between $2000 to $3000 or more. The price variation hinges on additional features like adjustable cutting sizes, durability, and ease of cleaning.

Related onion processing machines

The raw material of the onion ring cutter machine is usually clean onions that have been peeled and root-cut. So, to meet mass production, we need to use the following onion processing equipment to do peeling and root cutting first.

Small onion peeling machine

This small onion peeling machine is also called a semi-automatic onion peeler machine, which can quickly peel off the dry skin on the onion surface. When the machine works, workers need to manually add onions. The surface of the peeled onion is smooth and will not be damaged. The output of this semi-automatic onion peeler is between 50kg/h and 350kg/h.

Automatic large onion peeler machine

The output of this automatic onion peeling machine is usually relatively large, and its hourly workload is between 200kg and 1000kg. This large onion peeling equipment has an automatic lifting system, which can gradually lift the onions to the peeling system and quickly peel them. The peeling efficiency of the electric onion peeler can be as high as 98%.

Onion root cutting machine

The electric onion root cutter can cut off both ends of the onion. It is very suitable for use in restaurants and food processing plants, and can quickly process large amounts of onions. The cut surface of the onion processed by the onion root cutting machine is smooth.

Why choose the onion ring cutting machine?

- These machines offer unparalleled precision and efficiency in slicing onions, streamlining meal prep, and enhancing presentation.

- The benefits of opting for an onion ring cutting machine include increased productivity due to its swift and consistent slicing capabilities.

- These machines are designed to cater to different onion sizes and types, providing versatility in culinary applications.

- The precise cutting mechanisms ensure uniformity in slice thickness, which is crucial for dishes requiring consistent onion sizes.

Note for the onion ring processing machines

- There are many models of onion ring cutting machines. And different types of onion ring cutter machines have different processing capacities. Therefore, customers should choose the appropriate machine model according to their processing needs.

- Onion peeling machines and onion root cutters are commonly used equipment for mass processing onions. These machines are also necessary equipment for the industrial fried onion ring production line.