Are you tired of seeing your profits shrink due to food spoilage and freezer burn? This was the exact frustration facing a growing artisanal meat processor in Toronto, Canada, before they integrated our heavy-duty vacuum packing machine into their production line.

By upgrading from simple tabletop sealers to our industrial-grade solution, the client successfully transformed their packaging process. This investment in a professional commercial vacuum sealer not only extended the shelf life of their products by weeks but also elevated the visual appeal of their packaging.

Customer Background and Needs Analysis

Canada maintains some of the world’s strictest food safety regulations, enforced by the CFIA (Canadian Food Inspection Agency). The client operates in a competitive market where product freshness and presentation are paramount.

They specialize in cured meats and sausages, but were struggling with oxidation and package leaks using their old equipment. This limited their sales radius to local farmers’ markets. They urgently needed a food packaging equipment solution that could handle high volumes, create a hermetic seal strong enough to withstand cold chain logistics, and accommodate various bag sizes.

Specifically, they required a machine that could operate efficiently on Canadian power standards and offer gas flushing capabilities to protect delicate textures.

Our Solution

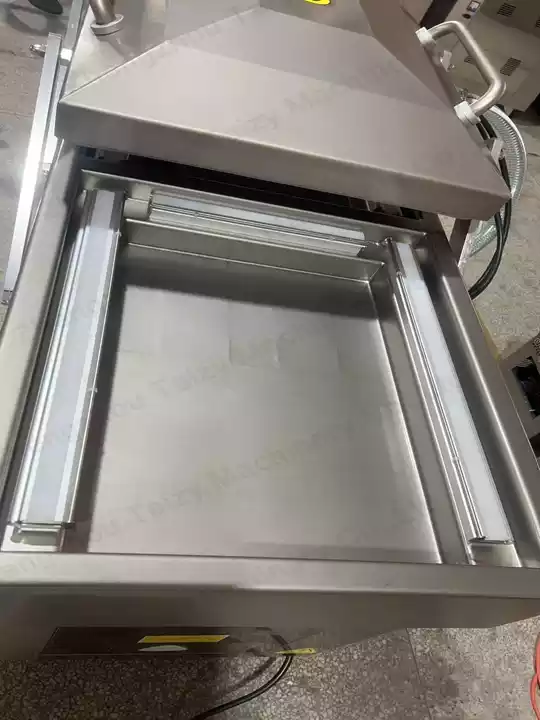

To meet the client’s demand for high output and versatility, we recommended our Double Chamber Vacuum Packing Machine. This design features two sealing chambers and a swinging lid, allowing the operator to load bags in one chamber while the machine vacuums and seals the other.

This effectively doubles the packaging speed compared to single-chamber models. We equipped the vacuum sealer machine with a high-performance vacuum pump capable of reaching near-zero oxygen levels rapidly. Additionally, we integrated a gas flush kit, allowing the client to inject inert gas (like Nitrogen) for products that require a “cushion” to prevent crushing.

Taizy Vacuum Packing Machine Advantages

Our industrial vacuum sealer was chosen for its rugged build and compliance standards. The entire machine body is constructed from extra-thick 304 stainless steel, ensuring durability and easy sanitation—critical for meeting Canadian hygiene codes.

A major advantage for this project was our electrical customization; we replaced the standard motors with ones rated for Canada’s specific voltage, ensuring seamless compatibility with their facility’s power grid.

Furthermore, the vacuum packing machine features a specialized 10mm wide heating wire, creating a broad, secure seal that virtually eliminates the risk of leakage during transport.

Customer Feedback and After-Sales

The successful implementation of this machine has been a game-changer for the client. Upon arrival, our technical team provided remote video support to guide them through the programmable control panel settings.

They were particularly impressed with the professional look of the vacuum-sealed packages, which has helped them gain shelf space in major supermarket chains. The client expressed their satisfaction with our attention to detail regarding voltage customization and packaging, stating that the machine worked perfectly right out of the box.