The automatic hamburger patty machine is also known as a hamburger forming machine. It is an efficient food processing machine and is mainly used to press various fillings and meat stuffings into cakes of various shapes. By simply replacing different extrusion dies, the vegetable pie maker machine can produce round, heart-shaped, oval, square, star-shaped, flower-shaped, and various animal pattern shapes of meat patties and vegetable patties.

Applications of the hamburger patty machine

The commercial patty forming machine is very suitable for small and medium-sized food processing plants, fast food stores, restaurants, etc.

This hamburger patty machine can squeeze all kinds of ground meat, meat paste, and meat pieces into meat patties, such as beef patties, hamburger patties, fish patties, chicken nuggets, chicken steaks, fish steaks and so on.

In addition, the meat patty machine can also make all kinds of vegetable patties, such as potato patties, pumpkin pies, vegetable burger patties, etc.

Technical parameter of the hamburger patty forming machine

| Model | TZ-100 |

| Power | 1.1kw |

| Capacity | 200-600kg/h |

| Cost time | 15-55min/time |

| Thickness of production | 6-25 mm |

| Dimension | 2828*830*2136mm |

| Weight | 100kg |

Note: this meat patty maker machine has different capacities and models, we can also customize this machine based on the customers’ actual requirements. This TZ-100 is the most popular one we sold until now.

How does the automatic hamburger forming machine work?

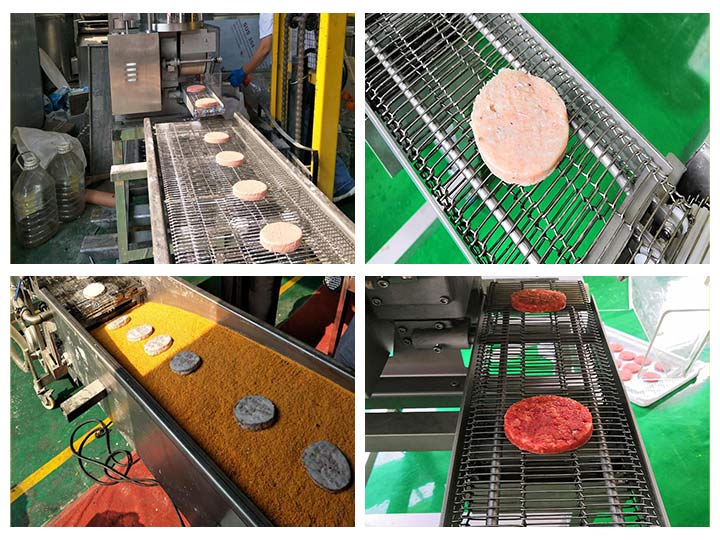

The main structure of the meat and vegetable cakes forming machine includes a feed barrel (with an automatic stirring shaft inside), a forming mold, a mesh belt conveyor, an electric control board, a motor, etc.

When the hamburger molding machine is working, we need to put the processed meat filling into the machine’s feed bucket in advance. The meat stuffing is continuously stirred by the stirring shaft in the bucket, and a certain amount of meat stuffing is filled into the forming mold below.

Then, the meat filling in the mold is quickly squeezed into a cake shape and dropped onto the mesh belt conveyor for discharging. The extruded meat patties can be further dipping, floured (bread crumbs) and fried to make delicious meat steaks.

Main features of the vegetable & meat pie maker

1. The design of the automatic meat patty machine is very delicate and highly automated. It can automatically complete the filling, forming, and discharging process of the patties making.

2.The hamburger patty forming machine is very versatile and can make all kinds of patties and vegetable patties. In addition, due to the high cost performance of the machine, simple operation and long service life, the sales of the machine in the domestic and foreign markets are very good.

3. The shape of the patties processed by this patty making machine is diverse, and customers can choose a multi-component mold according to their needs. In addition, the diameter of the processed patties is between 0-100mm, and the thickness can be adjusted.