Shrimp crackers are a kind of snack suitable for all ages. In China, a plate of shrimp crackers is often prepared during the festival, and the children will eat them up quickly. So how are prawn chips made? Our company has developed a complete shrimp chips production line, including many specializing in making prawn crackers. Prawn cracker making machine is highly automated and very popular with consumers.

Raw materials of shrimp chips production line

The main raw materials used in the shrimp chips production line are fresh shrimp meat, shrimp oil, shrimp shells, salt, pepper, corn starch or tapioca starch, monosodium glutamate and water. Adding starch during the production process can help the shrimp slices to form, and can improve the swelling degree of the shrimp chips after frying.

Adding shrimp meat and shrimp oil increases the nutritional value. The addition of salt and monosodium glutamate is mainly used to increase the flavor. In addition, food coloring can be added to make various colors of shrimp slices.

Main processing steps of prawn crackers production line

- First, use a blender to blend the ingredients for making the shrimp chips.

- The mixed raw materials are then extruded and matured with an extruder, and a cylindrical billet is extruded through a tool.

- The cylindrical raw material is then fed into the molding machine. The main machine of the forming machine produces shrimp strips with a diameter of 2cm-5cm by extruding the billet.

- Then the shrimp strip cutting machine cuts the shrimp strips into 50cm-150cm long strips.

- Finally, use a slicer to cut the shrimp strips into shrimp slices with a thickness of 0.6mm-3.5mm.

Main machines of shrimp chips production line

The function of the extruder is to make the mixed raw materials into cylindrical blocks. The raw material is first poured into the feeder device, and the raw material is extruded through the host machine.

During this period, the raw material will be cooked, and the clinker will be squeezed through the die again, and finally a cylindrical billet will be formed.

The host will squeeze the blanks into the forming machine, and then pass through the mold to make shrimp sticks with a diameter of 2cm-5cm.

This is a shrimp stick cutter. It can adjust the length of the cutting rod according to the requirements, and the length of the cutting rod is between 50cm-150cm.

This is the machine that further processes the prawn sticks into prawn chips. Its slice thickness is adjustable, and the general thickness is 0.6mm-3.5mm.

This is the shrimp chip dryer. The conveyor belt in the machine is made of 304 stainless steel, with a total of 5 layers

Effective drying area: 52.5㎡. The dryer can work efficiently and ensure food safety.

Parameters of prawn crackers production line

| Items | Power | Size | Weight |

| Mixing machine | 3.0kw | 1050*910*1150mm | 110kg |

| Extruder | 20.7kw | 1850*810*1950mm | 730kg |

| Forming machine | 5.5kw | 850*540*790mm | 250kg |

| Prawn stick cutter | 1.3kw | 1550*540*790mm | 150kg |

| Dryer | 75kw | 8530*1320*2470mm | 2000kg |

| Conveyor | 0.37kw | 2320*740*2220mm | 200kg |

| Screen machine | 13kw | 2500*935*1625mm | 500kg |

The parameters shows the main data of equipment in shrimp chips production line. The data above are the most popular type, our company can also provide other type prawn cracker making machine and its related equipment. If you are interested, consult us any time.

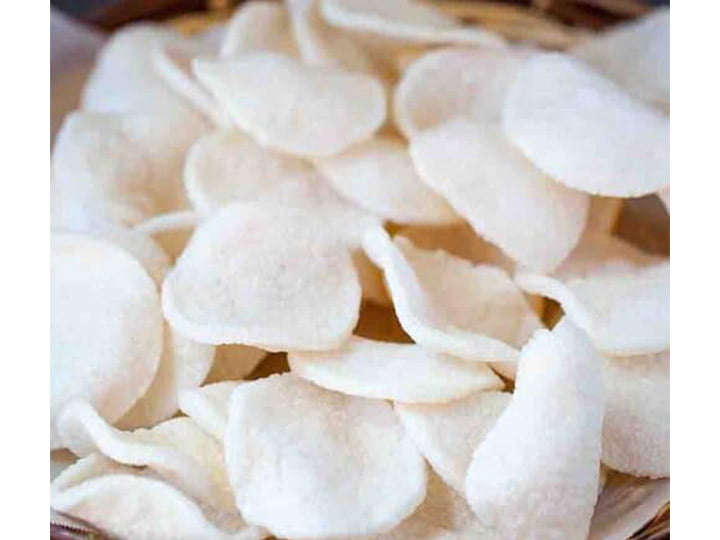

final Product of prawn crackers production line

This prawn chips production line can make colorful shrimp chips by adding various colors of food coloring. After drying, the shrimp chips are relatively hard, and will become fluffy and much larger after frying.

Are shrimp chips healthy?

As a special puffed food, shrimp chips have attracted many people’s welcome. The taste of shrimp chips is relatively delicious, and it is also a good choice as a small snack in our daily life.

Shrimp chips are nutritious. Fresh shrimp meat and shrimp oil are added during the production process. After deep-frying, they have high heat and can quickly replenish physical strength. But it is a puffed food with high calories. If you eat too much at one time, there will be a risk of obesity. Therefore, wrapping shrimp chips during leisure can still supplement the nutrients needed by the human body.

Prawn cracker making machine Factory display

Our factory is located in Zhengzhou City, Henan Province. The factory is clean and bright, and the produced shrimp chips making machines will be placed in our own warehouse. Welcome to visit the factory. If it is not convenient for on-site inspection due to various factors, we can ask our sales staff to take the test video and pictures of the prawn cracker making machine.