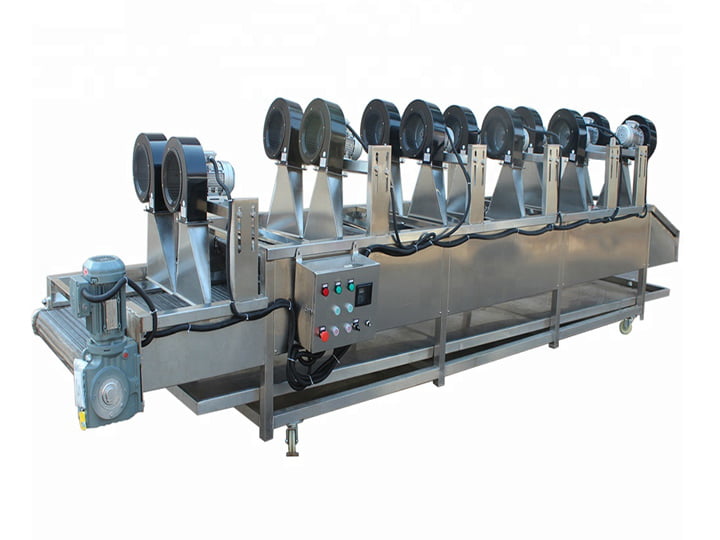

The electric air-drying and cooling machine is commonly used in food processing and industrial production. The automatic air dryer can be widely used in fruit and vegetable cleaning lines, packaged food sterilization lines, and fried food cooling lines. It has the characteristics of high efficiency, fast speed, simple operation, and easy maintenance.

Applications of the air-drying and cooling machine

This main functions of the automatic air dryer are fast dewatering and cooling so that it is widely used for various food processing plants.

For drying(dewatering)

In large-scale fruit and vegetable washing and processing plants, this air dryer is very practical. It can use the strong wind to remove residual water droplets on the surface of fruit and vegetables. Similarly, for the packaged food after pasteurization, the air dryer can also dry the water droplets on the surface, and the dried food can be directly packaged.

For fast cooling

In the fried food processing line, the air dryer is often used to quickly cool the fried food. Normally, when the fried food passes through the electric air-drying and cooling machine, the temperature can quickly drop to room temperature.

Technical parameter of the fried food dryer

| Model | TZ-510 | TZ-520 |

| The Speed adjustment mode | manual speed adjustment | manual speed adjustment |

| Number of fans | 12 fans | 10 fans |

| Power | 12KW, 380V / 50Hz | 7.5KW,380V / 50Hz |

| Material | high-quality food-grade stainless steel | high-quality food-grade stainless steel |

| Size | 6000×1700×1500mm | 3500x1200x1400mm |

Main features of the air-drying and cooling machine

1.The electric air dryer has many specifications and models, so customers can choose according to their actual needs. We can also customize the machine according to customer needs, where the width and length of the mesh belt of the air dryer and the number of fans can be set at will.

2. The automatic fried food cooler is all made of SUS304 stainless steel, so it is very resistant to wear and corrosion, with a low failure rate and a long service life.

3. When the machine is in use, the speed of its mesh belt can be adjusted, and customers can set different operating speeds according to the materials to be processed, so as to achieve better air-drying and cooling effects.