The buckwheat crackers (crisp chips) production line is a set of equipment specialized in producing fried tartary buckwheat chips. This commercial buckwheat chips making machines mainly include an automatic hoisting machine, a continuous frying machine, a rotary seasoning machine, a cooling machine, and an automatic packaging machine.

What are the puffed and fried buckwheat crisps?

Tartary buckwheat crackers are made from buckwheat flour. The buckwheat flour is first puffed into crisps, and then fried in hot oil until crispy, and then seasoned for consumption. Tartary buckwheat chips have a crisp taste and high nutritional value. Besides, its food value and medicinal value are very high. The buckwheat crisp is a delicious snack for all ages.

How to make buckwheat chips?

The processing of buckwheat chips requires a complete set of equipment, including automatic hoist, fryer, seasoning machine, air dryer, and packaging machine. The raw material of the buckwheat crackers production line is the puffed Tartary buckwheat flakes. The specific processing flow is as follows:

Step 1: Hoist conveyor lifting

The Tartary buckwheat flakes are semi-finished products that have been puffed before being lifted by an automatic hoist. Generally, customers need to pre-treat the tartary buckwheat flour with powder mixer and puffing machine and process them into puffed crisps. Then, the buckwheat flakes are transported to the fryer by a hoist for frying.

Step 2: Continuous frying

We use this continuous fryer machine to fry the puffed buckwheat chips. This mesh belt type frying machine is the most efficient equipment for frying all kinds of food. It can be heated by electricity or gas. When frying the buckwheat crackers, the frying temperature is about 180℃, and it should be preheated to this temperature for continuous production. When frying the chips, each batch will last about 5 minutes.

Step 3: Automatic seasoning

After frying, the fried buckwheat chips will be oily with big oil droplets, so we can use an electric deoiling machine to remove the excess oil. Then, we use the rotary seasoning machine to mix the fried buckwheat crackers with seasonings(most made in a certain recipe). This automatic seasoning machine has the special functions of automatic weighing and adding the seasoning powder.

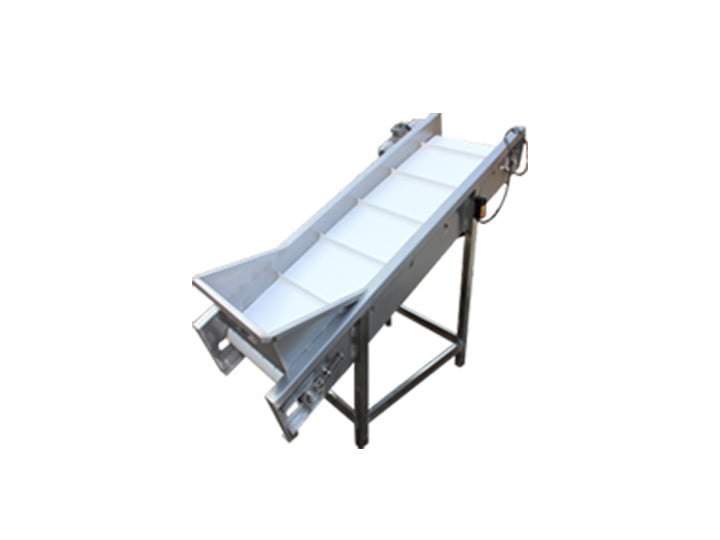

Step 4: Air cooling

Before packaging the buckwheat chips, we should cool down its temperature to the room temperature, therefore, we can use this air-drying and cooling machine. This cooling machine has multiple groups of fans, which will blow strong wind(cold or hot) to the fried food and lower their temperature quickly.

Step 5: Buckwheat crackers packaging

The last step is to pack the finished buckwheat chips into bags. The most efficient equipment we use is this automatic packaging machine, which has high efficiency for package various snacks in food processing plants. Except for packaging the buckwheat chips into bags, it also can type the date to the packing bags and fill the bags with nitrogen.

Main features of the buckwheat chips production line

- The full set of buckwheat crackers making machines are made of high-quality 304 stainless steel so that they are very durable and anticorrosive.

- This buckwheat chips production line we described here is just the regular arrangement we sold. We can also customize this line based on your actual requirements, such as fully-automatic buckwheat crisps processing line, semi-automatic buckwheat chips line, 200kg/h buckwheat crackers line, etc.

- This fried snack processing line is not only suitable for making fried buckwheat chips but also suitable for making other kinds of fried food, such as rice crust, fried chicken legs, and so on.