The automatic French fries production line is your all-in-one system for converting raw potatoes into top-tier French fries. It streamlines every step, including washing, peeling, cutting, frying, and freezing, into a single, continuous workflow. The result is consistently uniform fries with a desirable crispy texture and dependable production rates.

এই লাইনটি 300 থেকে 2000 kg/h পর্যন্ত প্রক্রিয়াজাত ক্ষমতা প্রদান করে, এটি বিভিন্ন ব্যবসায়ের জন্য উপযুক্ত.

French fry production line working video

application of the frozen French fries

The frozen French fries produced by our line are in high demand across the entire food industry:

- Restaurants and catering: from global fast-food franchises to local restaurants, hotels, and caterers.

- Supermarket sales: for sale directly to consumers in the frozen food sections of retail grocery stores.

- Private label production: for other companies to package and sell under their own brand name.

Potato chips Production process Flow

Our potato chips processing plant breaks down the complex french fry processing into ten precise automated steps, each seamlessly integrated with the next.

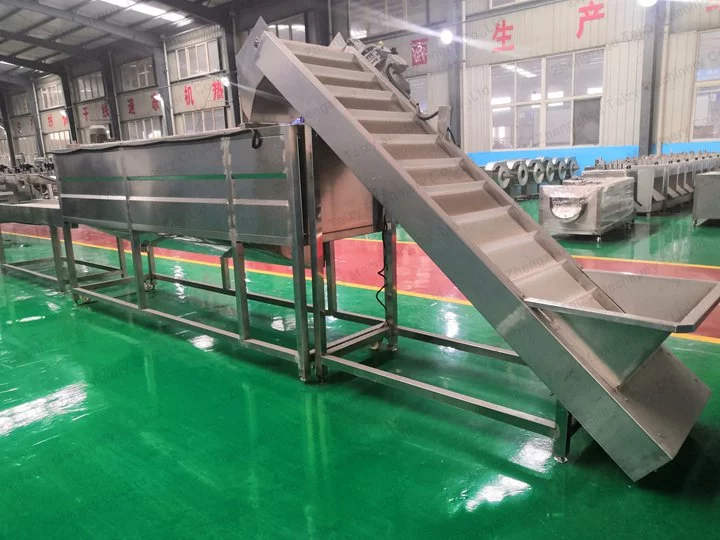

Lifting and Feeding

Fresh potatoes are poured into the hopper and automatically and evenly fed into the washing and peeling machine via the elevator, initiating the first step of automated production.

Washing and Peeling

Utilizing a brush roller washing and peeling machine, combined with spray water, efficiently removes soil and outer skin from potato surfaces while minimizing raw material loss.

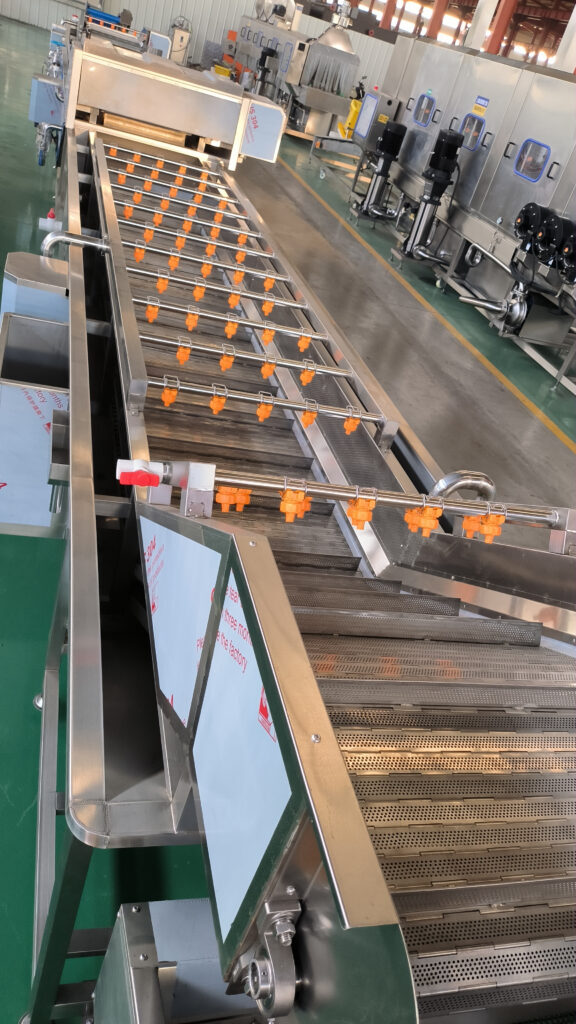

Picking and Sorting

Peeled potatoes move slowly along the sorting conveyor belt, where workers can easily remove defective potatoes with spots, sprouts, or incomplete peeling.

Cutting

Using a high-speed potato slicer, potatoes are rapidly and uniformly cut into French fries of the desired dimensions (7x7mm to 12x12mm), with smooth surfaces and no damage.

Rinsing

The cut fries enter the rinsing machine to remove surface free starch, preventing sticking and excessive oil absorption during frying, and laying the foundation for a crispy texture.

Blanching

French fries are in a blanching machine at precisely controlled temperatures and times. This step deactivates enzymes, preserves the fries’ natural color, and ensures more uniform cooking throughout for superior texture and taste.

Air Cooling and Dewatering

After blanching, the fries pass through a high-powered air dryer to rapidly remove surface moisture. This prevents hot oil splatter during frying and ensures more efficient cooking with superior crispiness.

Continuous Frying

This is the core process that determines the final texture and color of French fries. The continuous fryer employs oil-water separation technology and an automatic temperature control system to ensure fries are fried and set at a constant optimal oil temperature, resulting in a golden, uniform color.

Vibrating De-oiling

Freshly cooked fries pass through a vibrating de-oiling machine, which uses high-frequency vibrations to effectively remove excess surface oil, resulting in a crispy, non-greasy texture.

Quick Freezing

After oil removal, the fries are rapidly transferred into quick-freezing cabinets. Within a very short time, their core temperature drops below -18°C, locking in flavor and texture to prepare them for long-term storage and transportation.

Taizy French Fries Processing Plant Core Advantages

- Integrated automation: the line operates as a continuous, automated system, reducing process variability and dependence on manual labor.

- স্কেলযোগ্য উৎপাদন ক্ষমতা: আমাদের লাইনগুলি আপনার নির্দিষ্ট স্পেসিফিকেশনের জন্য ডিজাইন করা হয়েছে, স্কেলযোগ্য আউটপুট সহ ৩০০ কেজি/ঘ থেকে ২,০০০ কেজি/ঘ এর বেশি যেকোনো বাণিজ্যিক চাহিদা পূরণের জন্য।

- উন্নত স্যানিটারি নির্মাণ: সমস্ত খাদ্য-সংস্পর্শ উপাদান তৈরি করা হয় ৩০৪ স্টেইনলেস স্টীল, সম্পূর্ণ সম্মতি নিশ্চিত করে জিএমপি, এইচএসিপি, এবং অন্যান্য খাদ্য নিরাপত্তা প্রোটোকল।

- সম্পদ-সর্বোত্তম পারফরম্যান্স: প্রতিটি যন্ত্রকে শীর্ষ দক্ষতার জন্য ডিজাইন করা হয়েছে, যা পরিমাপযোগ্য পানি, তেল, কমানো, এবং শক্তি প্রতি কিলোগ্রাম আউটপুটের জন্য খরচ।

- বহু-উৎপাদন প্রক্রিয়াকরণ ক্ষমতা: ডিজাইনের অন্তর্নিহিত নমনীয়তা সহজ পরিবর্তনের জন্য অনুমতি দেয় যাতে বিকল্প পণ্য প্রক্রিয়াকরণ করা যায়, যেমন আলু চিপস অথবা মিষ্টি আলু ফ্রাই, লাইনটির সামগ্রিক কার্যকারিতা বৃদ্ধি করে।

Potato Chips processing plant price

The cost of a French fries production line is comprised of two main parts: the core processing machines and the necessary auxiliary equipment (e.g., conveyors, oil filters, packaging machines).

We customize the entire line based on the customer’s target output. The scale of the equipment and the final price are determined by your specific production capacity requirements. For a precise quote, please contact us with your details.

FAQ

Can this production line make potato chips?

Yes. Simply replace the cutter with a slicer to produce potato chips.

What if I don’t need freezing?

No problem. We can provide you with a “fresh fries” production line that doesn’t include quick-freezing. The equipment configuration is more flexible, and the investment cost is lower.

What is the capacity range of the French fry line?

From 300 kg/h to 2000 kg/h.

Does this production line consume a lot of oil?

Not at all. Our deep fryers are equipped with an automatic residue scraping and filtration system that continuously filters debris from the oil, significantly extending its lifespan.

Contact Us for Solutions

Our team of professional engineers stands ready to provide complimentary consultations and design the most cost-effective production line solutions tailored to your needs.

Reach out today to kickstart your path to success!